Aircraft Power Systems are undergoing rapid development, from conventional generators and wiring harnesses to advanced electrical propulsion and IIoT based diagnostics. As aviation shifts towards electric and hybrid propulsion, ensuring electrical safety in aviation has never been more critical. Robust systems must now not only power aircraft effectively but also prevent faults, arcs, and overheating that can lead to in-flight emergencies.

The Rise of Electric Aircraft and Their Impact on Safety?

Technology plays a crucial role in improving Aircraft Power Systems and ensuring safety within the aviation industry. From advancements in aircraft maintenance to the emergence of electric aircraft for sustainable and safe flights, technology impacts all aspects of aviation research and development.

The aviation industry is experiencing a surge in the development of electric aircraft. From light trainers like the Pipistrel Velis Electro (an electric-powered aircraft) to emerging electric aircraft propulsion systems in hydrogen-electric and hybrid formats, the future of flying is becoming more electric and eco-friendlier.

Electric systems promise cleaner skies, lower operational costs, and quieter operations. However, they have also introduced new safety challenges, such as complex high-voltage architectures, energy-dense battery systems and thermal management under fluctuating flight conditions. Unlike traditional jet engines, electric propulsion must rely on tightly integrated systems of motors, inverters, and control electronics, demanding even higher safety precautions.

Understanding Electrical Hazards in Aviation Industry

Even traditional aircraft face electrical risks, including short circuits, arc faults, and overheating. In the modern aviation industry, these risks are magnified by the use of high-voltage systems and powerful lithium-ion battery packs. An electrical Hazard is something that has the potential to cause harm or contribute to causing an aircraft accident. For better understanding, let’s take the example of an aircraft. The hazard that is present in an aircraft could be its electric wiring, which has the potential to cause electrocution or fires. When it comes to the airport, wet flooring is a hazard that can contribute to people slipping and may cause serious harm or injuries.

Key electrical hazards include in electrical aircraft:

- Short Circuits- Can be caused by corrosion, damaged insulation, or component failure.

- Arc flash/blast – If not detected quickly, dangerous electric discharges can lead to intense heat and cause fire.

- Thermal Runaway: Chain reaction within battery packs can result in overheating and combustion.

Due to dense battery architecture, electrical aircraft are more vulnerable to these hazards. Therefore, specialized safety measures must be implemented to prevent catastrophic failures.

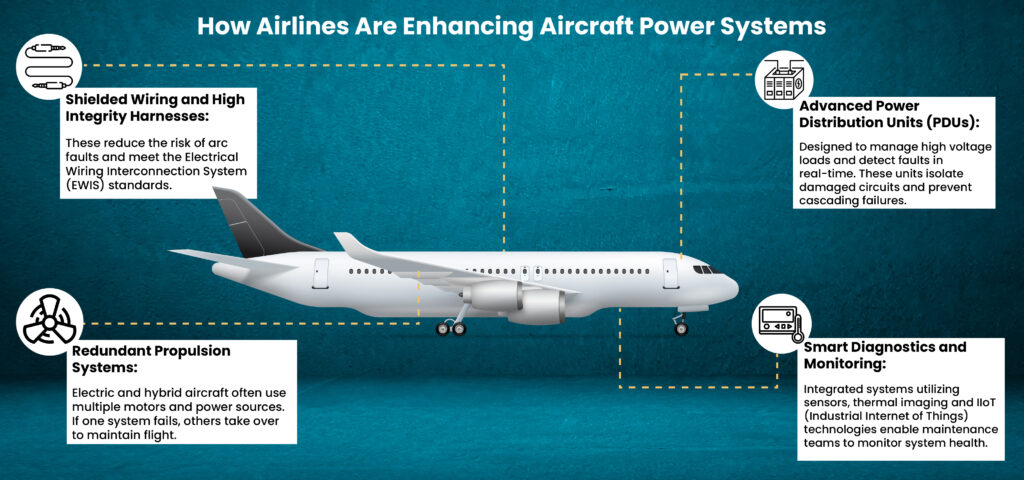

How Airlines Are Enhancing Aircraft Power Systems?

To enhance the reliability and safety of Aircraft power systems, airlines and aerospace manufactures are taking proactive steps to address the challenges:

- Shielded Wiring and High Integrity Harnesses: These reduce the risk of arc faults and meet the Electrical Wiring Interconnection System (EWIS) standards.

- Advanced Power Distribution Units (PDUs): Designed to manage high voltage loads and detect faults in real-time. These units isolate damaged circuits and prevent cascading failures.

- Redundant Propulsion Systems: Electric and hybrid aircraft often use multiple motors and power sources. If one system fails, others take over to maintain flight.

- Smart Diagnostics and Monitoring: Integrated systems utilizing sensors, thermal imaging and IIoT (Industrial Internet of Things) technologies enable maintenance teams to monitor system health.

Industry Standards and role of regulations implemented for Aircraft Power systems

Aviation regulators worldwide are adapting quickly to the shift toward electrification. Several key initiatives have been introduced to ensure that new aircraft designs meet rigorous safety standards:

- FAA and EASA Guidelines: These regulatory bodies have developed frameworks such as the Special Federal Aviation Regulation (SFAR) for electric and powered-lift aircraft, addressing wiring, battery integrity, and propulsion system requirements.

- Design Assurance Standards: Standards such as DO-254 and ARP4754/4761 guide the design and verification processes for airborne electronic hardware and software, ensuring that every component undergoes a thorough safety analysis.

- ASTM Standards: New proposed standards for hybrid-electric propulsion systems aim to streamline certification, improve safety practices, and enable consistent testing across manufacturers.

These guidelines help ensure that aircraft developers integrate safety features at the design stage, not just after incidents or failures.

The Role of Electrical Safety in Aviation: A 2025 Ahmedabad Aircraft plane crash

Source: Ahmedabad Air India crash marks first fatal Boeing Dreamliner accident

Major Key Factors under Investigation

- Dual Engine Flameout: Both engines reportedly lost thrust shortly after takeoff, a rare event that led to a loss of propulsion and control.

- Electrical System Failure: The Boeing 787’s advanced “more-electric” architecture relies heavily on electrical power for engine control and other critical systems. Initial findings suggest possible generator malfunctions or power distribution faults may have contributed to the loss of engine control.

- Environmental Hazards: Bird strikes or foreign object damage during the critical takeoff phase are being explored as potential causes of engine failure.

- Fuel Contamination: Investigations are examining the possibility of contaminated jet fuel affecting engine performance.

Source: What led to Air India plane crash?

Importance for Electrical Safety in Aviation

These above cases underscore the importance of rigorous electrical safety protocols in modern aircraft, mainly as aviation increasingly adopts electric propulsion and complex power systems. The incident demonstrates the critical need for:

- Robust and redundant electrical power distribution systems.

- Real-time monitoring and predictive diagnostics to identify faults before they escalate.

- Comprehensive maintenance practices aligned with the latest regulatory standards.

How Advanced Monitoring Tools Can Help?

Manav provides intelligent electrical system monitoring solutions that could enhance aircraft safety by continuously tracking power system health, detecting faults early, and ensuring grounding systems are effective. While not a direct aviation supplier yet, the principles of proactive electrical fault detection and monitoring are universally applicable and critical to preventing similar failures in all High-reliability environments.

Future Trends of Electrical Safety in Aviation

As electric and hybrid aircraft power system, mature several emerging trends are shaping the future of aviation safety:

- AI-Based Fault Prediction: Advanced algorithms analyze data from sensors to identify early signs of insulation wear, connector corrosion, or battery degradation, allowing maintenance teams to intervene proactively.

- Next-Gen Battery Management Systems (BMS): Modern BMS not only monitors voltage and temperature but also balances cell performance, detects anomalies, and shuts down faulty modules to prevent accidents.

- Modular Propulsion Systems: Inverter-driven, distributed Electric Aircraft Propulsion designs enable aircraft to isolate and contain failures within a single module, thereby keeping the rest of the system operational.

- Solid-State Battery Innovation: New battery chemistries reduce flammable electrolytes, lowering the risk of fire and improving energy density.

Together, these technologies are driving a safer, more reliable future for electric aircraft and innovative aviation systems.

Conclusion

As the aviation industry moves towards a more electric, cleaner, more sustainable future, ensuring electrical safety in aircraft is more important than ever. By investing in smart technologies, by following global safety standards and learning from past incidents, industry is building a foundation for safer skies and improving the power distribution systems and adopting advanced monitoring tools, airlines and manufacturers are working hard to prevent electrical hazards before they become threats. With innovation driving change, the future of electric aircraft looks promising, not only for the environment but also for the safety of everyone on board.

Author – Sharada Banerjee