Railways remain one of the most complex engineered networks in the world—but despite technological upgrades, automation, modern signalling, and electrification, railway accidents continue to occur. While public discussions usually revolve around human error, track damage, mechanical faults, or signalling delays, a major contributor often goes unnoticed. “Hidden failures in the railway electrification system and grounding networks”.

Electrical safety is not always visible. But when grounding, earthing, or traction return systems fail, the entire railway ecosystem—from train movement to signalling can become unstable. This blog explores how railway electrification, railway grounding systems, earthing needed for railway systems, and overall electrical safety precautions directly influence safety, and why many accidents originate from these invisible electrical engineering gaps.

Objective of this blog:

To highlight how gaps in railway electrification, earthing systems, and railway grounding systems create unsafe operating conditions that can indirectly or directly cause railway accidents and harm people and assests.

Railway Accidents Are Still Rising, but the Real Causes Remain Invisible

Railway infrastructure depends heavily on electrical systems of signalling, communication, traction power, track circuits, interlocking controls, and safety equipment. When any of these systems malfunction due to poor grounding or unstable electrification, the consequences can be severe.

Most people assume accidents occur because of:

- Signal Passed at Danger (SPAD)

- Broken rails or track wear

- Rolling stock or brake failures

- Human error

- Communication delay or signal failure

- mechanical issues

But in reality, many of these visible failures are triggered by deeper electrical issues like fault currents, grounding failures, lightning surges, EMI and EMC disturbances, or unstable track circuits.

While these reasons are valid, they do not explain why signalling fails… or why track circuits become unstable… or why communication drops during storms. The reality is that many of these failures originate from hidden weaknesses in the electric train power supply and railway electrification system.

The Hidden Electrical Factors Behind Railway Accidents

Railway operations depend on precise electrical behaviour. Even a small deviation in grounding, earthing, or voltage can lead to incorrect detection, delayed response, or system malfunction.

1. Grounding Failures in Track Circuits and Station Devices: The Hidden Risk

Most people, even station staff, don’t realize that many signalling failures start underground, in the earthing system. When grounding becomes weak or unstable, several silent but serious issues begin:

- Axle counters may miscount due to electrical noise in the earth grid.

- Interlocking systems can freeze because of small, unseen voltage rise in the ground.

- Point machines may not lock properly when return-current paths are disturbed.

- Relay rooms may receive hidden surges, slowly damaging modules without visible burning.

- Telecom and ATS cables pick up interference, delaying commands, and feedback.

These problems are often mistaken for “software issues” or “equipment faults,” but in reality, they stem from poor earthing beneath the station.

A single grounding flaw can trigger false signals, unstable detection, and unpredictable equipment behaviour, all quietly increasing the chances of an accident long before anything becomes visible on the tracks. Such grounding issues directly impact the stability of the railway electrification system, leading to unreliable signalling behaviour.

2. Poor Earthing in Signalling Systems

Signalling systems rely on relays, interlocking logic, and communication channels that are extremely sensitive to noise and voltage fluctuations.

Poor earthing can result in:

- Protective devices fail to trip

- Higher risk of electrocution or equipment damage

- Wrong signal aspect

- Interlocking errors

- EMC/EMI interference

- Sudden signal blackout

- Continuous Signal blinking

All of these can misguide the train operator or the automatic system.

3. Unmanaged Fault Currents in Electrified Railways

In electrified sections, fault currents travel through rails, OHE structures, and the grounding network. When these currents are not managed properly:

- Relays fail to operate

- Protection systems delay

- Equipment may not isolate faults

- Voltage rises in the railway electrification system

- Failure of Electrical Audits

- Poor maintenance of electrical devices

4. Lightning Impact on Electrified Railway Assets

Railway infrastructure remains highly exposed, from OHE masts and signalling poles to track circuits, point machines, and ATS panels.

Railway infrastructure remains highly exposed — from OHE masts and signalling poles to track circuits, point machines, and ATS panels.When lightning strikes

- Surge energy damages signalling electronics

- Interlocking freezes

- Point machines malfunction

- System gives false clear or false occupied

- Electric train power supply becomes unstable

These disturbances severely affect the reliability of railway electrification, especially in high-speed and heavily trafficked corridors. Poor surge coordination and weak lightning protection are a major but underreported cause of railway failures.

What Happens When Railway Earthing Systems Fail?

The railway grounding system is the backbone of electrical safety. When it is weak, outdated, or poorly engineered, the entire ecosystem becomes vulnerable. A compromised earthing network increases electrical risks, disrupts signalling logic, and exposes people and assets to dangerous electrical conditions.

Ground Potential Rise (GPR/EPR) becomes one of the first major concerns during faults or lightning events. The voltage of the ground suddenly rises to dangerous levels, creating unsafe touch and step potentials around tracks, substations, and OHE structures. This rise in potential also disturbs sensitive control and signalling circuits, affecting both operational safety and system reliability.

When the grounding system cannot provide a low-resistance path, fault currents begin travelling through unintended routes. When this happens repeatedly, the performance of railway electrification weakens, causing unstable protection and signalling functions Instead of safely dissipating into the soil, they may enter signalling cables, control circuits, or metallic structures.

In poorly bonded or deteriorated systems, stray currents begin leaking into the surrounding metal parts, accelerating corrosion. Over time, rails weaken, fasteners deteriorate, and critical structures lose strength. This not only increases operational risk but also leads to a significant rise in long-term maintenance costs. Regular earth resistance testing becomes essential to detect such anomalies early and prevent system-wide failures.

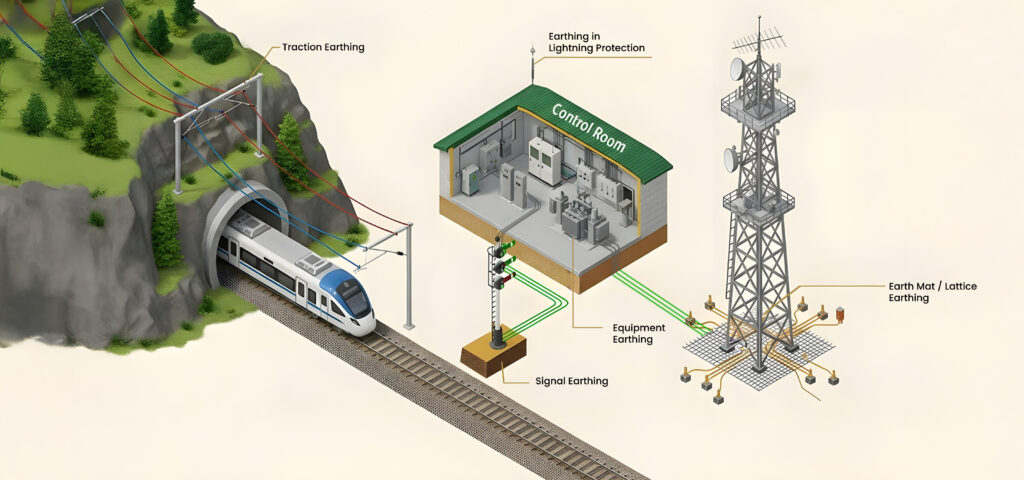

Critical Earthing Systems in Railway Electrification Infrastructure

Earthing (grounding) is one of the most critical safety components in any railway electrification system.

It protects:

- Personnel

- Signalling equipment

- Traction power assets

- Telecommunication networks

- Rolling stock

A failure in earthing can directly result in accidents, fires, equipment damage, or system blackout.

- Traction Earthing (25 kV AC): Ensures safe return current flow and reduces potential rise in the electric train power supply.

2. Signal Earthing: Stabilizes track circuits and reduces electrical noise.

3. Equipment Earthing: Protects relay rooms, ATS, UPS, telecom systems, and signalling equipment.

4. Earth Mat / Lattice Earthing: Controls touch & step potential at substations, stations, depots, and yards.

5. Lightning Protection Earthing: Protects OHE masts, station structures, and signalling assets from surges. A failure in any of these can disturb the entire railway electrification system.

Engineering Measures to Reduce Railway Accidents

Modern railway safety requires engineered electrical solutions.

1. Engineered Railway Grounding System Design

- Soil resistivity study

- Modelling ground grids

- Implementing lattice earthing

- Ensuring correct fault current dissipation

2. Earth Enhancing Compounds (EEC)

Maintains long-term stable resistance essential for signalling and traction. These engineered improvements significantly enhance the reliability of railway electrification and reduce operational risks

3. Lightning Protection and Surge Coordination

Designed for:

- OHE masts

- Traction substations

- Relay and communication rooms

4. Predictive Maintenance & Electrical Safety Precautions

Includes:

- Scheduled audits

- Earth resistance testing

- Compliance review

- Touch & step potential measurement

These precautions ensure long-term safety and prevent unexpected failures.

Case Insights on How Electrical Issues Lead to Real Railway Failures

At Manav, we ensure that railway earthing systems are engineered with precision and long-term reliability. Our process begins with a thorough, standards-driven design approach, in which we define the appropriate earthing method, conductor sizing, and optimal grounding locations for each railway network. We then take full responsibility for the complete implementation, laying conductors, integrating them into the electrical network, and ensuring every connection meets stringent safety norms. Once installed, our team conducts rigorous testing to verify the system’s resistance, continuity, and performance under real-world conditions.

Beyond installation, we maintain these systems through periodic inspections and technical evaluations to prevent failures and ensure consistent safety. With deep expertise in electrical safety, power systems, traction network transient studies, EM management, and operational-time simulations, Manav delivers comprehensive solutions, from design, supply, installation, and testing to commissioning and RCA, to keep railway infrastructure safe, resilient, and fully compliant.

Manav’s solution: Raising Railway Safety Standards with Advanced R-FERM-Based Earthing

Manav’s strengthens railway electrical safety by integrating its advanced technology R-FERM (Remote Fault Time Earth Resistance Monitor) into critical rail infrastructure. R-FERM enables precise assessment of earthing efficiency, soil behaviour, fault-current dissipation, and the overall health of grounding systems across stations, OHE masts, signaling cabins, level crossings, and traction substations.

By combining this product-driven intelligence with engineering services—such as grounding design, traction electrical audits, lightning protection planning, and fault diagnostics, Manav helps railway teams identify hidden hazards, reduce voltage rise risks, stabilize electrical performance, and achieve long-term compliance. With R-FERM, rail networks gain deeper visibility, safer operations, and significantly lower chances of electrical failures that contribute to railway accidents.

What Railway Authorities Can Do Immediately to strengthen railway safety

- Assess existing grounding and earthing systems

- Reinforce earth mats at substations

- Install proper surge protection

- Deploy continuous monitoring systems

- Maintain updated electrical compliance documentation

These steps create immediate safety improvements.

Conclusion

Railway accidents are not always caused by mechanical failure or human error. Many originate from hidden electrical failures. Strong grounding, engineered earthing, proper surge protection, and continuous monitoring are essential for safe operations.

A reliable railway electrification system depends on: Engineered grounding, Stable earth resistance, Effective lightning protection and Predictive monitoring. When electrical foundations are strong, railway operations become safer, more predictable, and more resilient. Strengthening railway electrification with proper earthing, surge protection, and monitoring can dramatically reduce accident risks.

– Author: Vigneshwaran S