The electric vehicle (EV) revolution is accelerating. Charging stations are popping up everywhere: public parking lots, highways, workplaces, and residential complexes. As more users demand fast charging, high power outputs, and convenient access, the infrastructure supporting EVs becomes more complex and more vulnerable if not properly designed. While fast charging grabs headlines, the earthing system for EV charging infrastructure is the unsung foundation that ensures everything works safely, reliably, and within regulatory norms.

With the increasing number of EVs, earthing for EV charging stations is not optional. It protects users from electrical hazards, shields EVSE (EV Supply Equipment) and batteries from damage. It ensures that protective devices like RCDs (residual current devices), circuit breakers, and surge protectors really do what they are meant to do. Let’s explore one of the most overlooked yet essential components of EV charging stations: proper earthing.

Why Earthing for EV Charging Infrastructure is Essential?

Electric vehicles are transforming mobility. As governments, businesses, and consumers push for more EV adoption, the build-out of EV charging infrastructure is accelerating rapidly. With this growth comes higher power demands, a wider variation in installation locations (outdoor, indoor, wet, dry, rural, and urban), and increased complexity in terms of safety, reliability, and regulatory compliance. In that context, earthing for EV charging infrastructure is not just a technical afterthought. It is the foundation that ensures safety, protects equipment, maintains reliability, and builds trust among users and stakeholders.

Many people talk about fast charging, power ratings, connector types, and charging speeds. But those are only safe and useful if the underlying earthing system for EV charging is effective. Without proper earthing, issues such as electric shocks, equipment damage, regulatory noncompliance, frequent failures, or worse, could undermine EV charging adoption. In this article, I’ll explain the technical essentials of earthing for EV charging stations, including how to design and maintain them, the standards involved, the challenges, and emerging trends. If you’re planning, installing, or operating EV chargers, this is what you need to know.

Growth of EV Infrastructure & Why Safety Matters:

EV adoption is increasing globally, including in India. To support this, authorities have introduced guidelines and mandates for the installation and operation of electric vehicle charging infrastructure. For example, in India, the Guidelines for Installation and Operation of Electric Vehicle Charging Infrastructure-2024, issued by the Ministry of Power, define responsibilities for manufacturers, owners, and operators, as well as safety and performance requirements, including safety devices and earth continuity monitoring.

As more high-power chargers (AC and DC) are installed, the risks multiply: higher fault currents, more complex power electronics, outdoor exposure (rain, humidity, dust), potential lightning transients, and varying soil conditions. The safety of users, integrity of equipment, and uninterrupted operation all depend heavily on how well the earthing system is designed, implemented, and maintained.

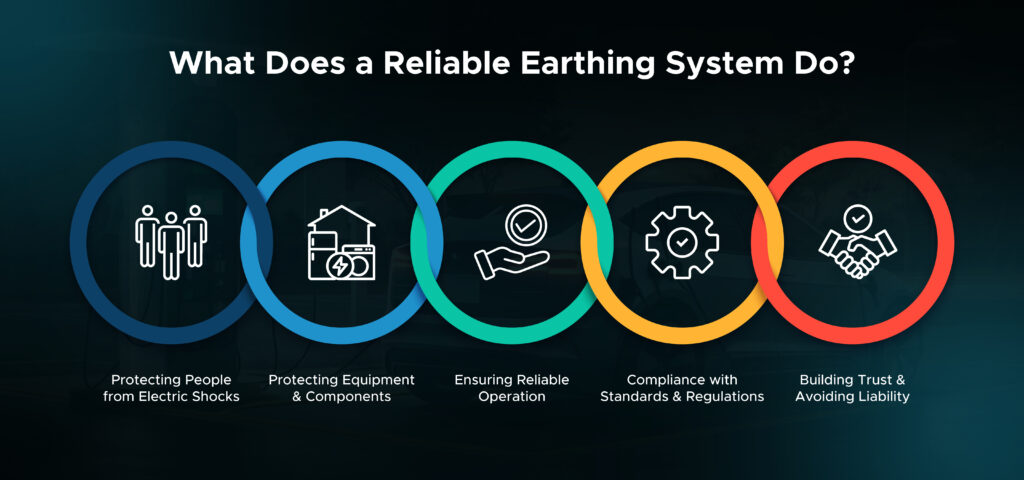

What Does a Reliable Earthing System Do?

Here are the main safety, reliability, and protection functions that earthing for EV charging stations must perform:

♦ Protecting People from Electric Shocks: If conductors leak current, or exposed metallic parts get accidentally connected to live parts, that current must have a low-impedance path to earth. Otherwise, human contact with metal parts can lead to dangerous touch voltages. In damp conditions (common outdoors) or when connectors or cables are exposed, risk increases. Proper earthing ensures that leakage or fault currents are safely directed to ground, rather than through a person.

♦ Protecting Equipment & Components: EV supply equipment (EVSE), chargers, connectors, and the vehicle’s battery management systems are all sensitive to voltage surges, transient faults, and improper grounding. Surges can come from lightning strikes or load fluctuation. A solid system for EV infrastructure earthing paths helps dissipate surge energy, reducing overvoltage stress on components and avoiding damage or a shortened lifespan.

♦ Ensuring Reliable Operation: Protective devices, such as Residual Current Devices (RCDs), ground fault circuit interrupters (GFCIs), circuit breakers, and surge protection devices (SPDs), all require a correct reference to the earthing system for EV charging infrastructure to detect faults effectively. If earth impedance is too high, detection may be delayed or fail; protection devices may nuisance-trip (causing downtime), or worse, fail to trip. That harm’s reliability.

♦ Compliance with Standards & Regulations: Globally, standards like IEC 61851 for EV conductive charging systems define requirements for safety, including protective earth conductors, earth continuity, insulation resistance, etc. In India, standards like IS 17017 (which covers general EV charging station safety, connectors, communication, and performance) align with IEC norms. Indian regulations also require earth continuity monitoring and mandate TN earthing system (protective earth reference) under certain provisions.

♦ Building Trust & Avoiding Liability: For users, a station that appears safe, is certified, adheres to norms, and has protective features instils confidence. For operators and investors, failures due to improper earthing can lead to legal liability, reputational damage, and financial cost (repairs, insurance, compensation). “Earthing for EV Charging Infrastructure” may not be visible to end-users, but it underlies the safety and trust that they rely on.

Key Components & Design of Effective Earthing Systems

Understanding what goes into a robust earthing system for EV charging infrastructure is essential for long term performance. Below are the technical elements and design considerations.

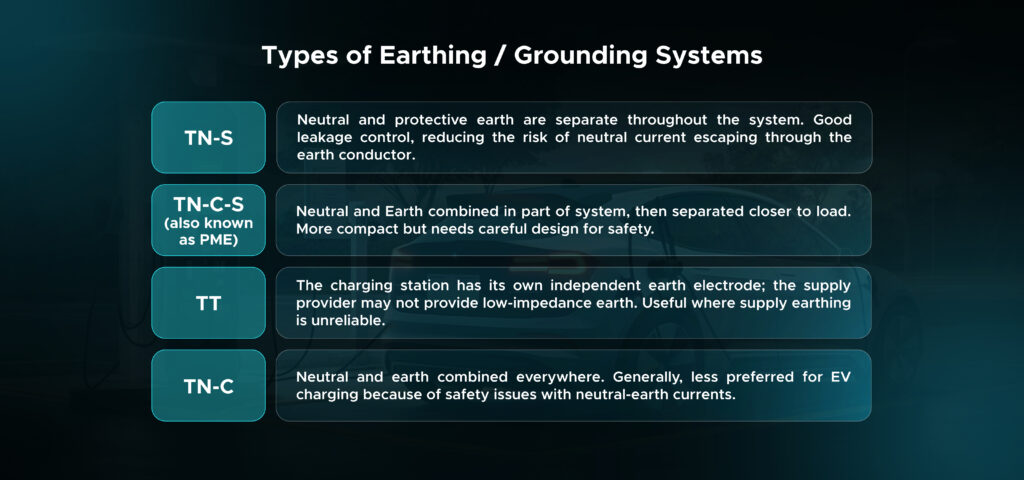

Indian codes/regulations (CEA safety recommendations) often require a TN system, as per IS 732, for EV charging stations.

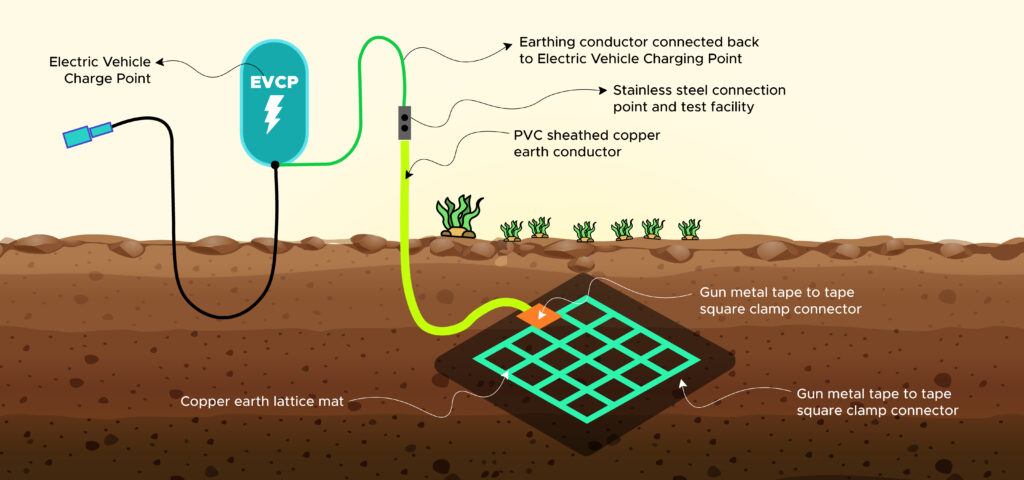

1. Earth Electrode Design, Conductors and Bonding

- Electrode choice: rods, plates, mesh, or combinations. Material: copper, copper-clad steel, or corrosion resistant coatings. Deeper or more extensive surface area improves performance.

- Electrode placement: depth, spacing, orientation. In many soils, deeper rods reduce resistance, but surface plates or mesh can complement vertical rods in shallow soil.

- Conductors and bonding: Protective Earth conductor sizing must follow standards (e.g. IEC guidelines, local IS). The conductor material must possess good conductivity, mechanical strength, and corrosion resistance. All exposed conductive parts of the charging station, enclosure, connectors must be bonded to earth.

2. Soil Resistivity and Earth Resistance

- Soil resistivity refers to the degree to which the soil resists the flow of electrical current. Low resistivity means soil supports good dissipation of fault current. High resistivity increases earth resistance and can create dangerous touch/step voltages.

- Techniques such as the Wenner four-point test, Schlumberger methods, and fall-of-potential methods are used to measure resistivity profiles at various depths.

- Design target values for earth resistance depend on fault current levels, safety limits, and the specific environmental conditions. Often, values below 10 ohms are preferred, and, in some cases, even lower resistance is needed.

Design and Installation Best Practices

Best practices in earthing for EV charging infrastructure include soil resistivity tests, electrode placement, bonding, and proper conductor sizing:

- Begin soil resistivity testing at the site(s) using reliable methods (e.g., Wenner 4-point). This helps design proper electrode size, depth, spacing.

- If soil resistivity is high, increase the electrode depth or use multiple rods/plates. Consider chemical backfill or conductive media to lower the resistance.

- Select the proper earth electrode configuration, such as vertical rods, horizontal plates/mesh, or a combination, depending on the site’s space, soil conditions, and expected fault currents.

- Size conductors (protective earth, bonding) to handle fault currents, mechanical stress, temperature. Use copper or copper-clad materials for their conductivity and durability.

- Ensure that all metallic parts and enclosures are bonded to the earth; connectors and charging plug shells must be connected to an earth conductor.

- Install earth continuity monitoring systems to detect any loss or degradation of earth path. Integrate monitoring with safety interlocks/disconnects.

- Use proper safety devices, such as RCDs (≤30 mA), SPDs, overcurrent protection, and circuit breakers, in coordination with the earth system.

Maintenance, Testing and Health of Earthing Systems

Even the best-designed earthing system degrades over time if not properly maintained.

- Periodic inspection of electrodes, joints, clamps, conductors for corrosion, looseness, physical damage.

- Measure earth resistance and impedance at intervals. If earth resistance rises beyond acceptable bounds (site-specific), remedial action (e.g. additional electrodes, improved materials) is needed.

- Test RCDs, SPDs, breakers regularly; simulate leakage or fault where safe / possible. Ensure devices trip properly.

- Maintain records of tests, inspections, changes. Regulatory guidelines in India require the recording of information for EVSE installations.

For installations where uptime and safety are critical, predictive maintenance offers a more innovative alternative to routine checks. Advanced Solutions like R-FERM enable continuous monitoring of earthing system health, identifying earth faults or degradation before they become failures.

Common Challenges and Solutions in Earthing for EV Charging Infrastructure

Even with good design and intention, real-world challenges frequently arise. Here are some to watch out for, and ways to mitigate them:

| Challenge | Solution |

|---|---|

| High soil resistivity (rocky, sandy, or dry soils) | Use deeper electrodes, multiple rods, chemical earthing compounds, or conductive backfill |

| Limited space in urban or compact installations | Install vertical rods, shallow plates, mesh under pavement/concrete, shared grounding with proper design, or modular earth pits |

| Corrosion and environmental deterioration (moisture, salts, pH) | Choose durable materials (copper, copper-clad steel, galvanized), apply protective coatings, seal enclosures/joints, and ensure regular maintenance |

| Outdoor environmental exposure (UV, rain, temperature changes) | Use weatherproof enclosures, connectors with high IP ratings, and seal joints effectively |

| Regulatory / standard changes (IS 17017, CEA guidelines, etc.) | Retrofit installations when needed and stay updated with evolving standards and compliance requirements |

Standards, Legal Requirements and Norms

To ensure safety, reliability, and legal compliance, it is essential to adhere to relevant standards for earthing in EV charging infrastructure.

- IEC standards: IEC 61851: General requirements for EV charging, conductive charging system definitions, protective earth conductor requirements, etc.

- IS / BIS standards in India: IS 17017 covers general requirements for EVSE including safety, connectors, communication.

- CEA / Government of India guidelines: Guidelines for Installation and Operation of Electric Vehicle Charging Infrastructure-2024 mandate safety, including earthing / earth continuity monitoring, TN system type, protective devices.

- Standards regarding soil resistivity measurement, electrode materials, protective devices commonly align with international best practices.

Following these standards ensures that the design of earthing system for EV charging meets safety thresholds (touch and step voltages, fault current dissipation), prevents legal or insurance problems, and ensures interoperability and acceptability of installations.

Emerging Trends and Innovations

The future of earthing system for EV charging is seeing some technological innovations:

- Automated earth continuity monitoring hardware embedded in EV chargers for real-time detection of earth path failures or deviations.

- IoT sensors monitor soil moisture, electrode temperature, joint resistance, and corrosion metrics in real-time, enabling predictive maintenance.

- Electrode materials or designs, including composite or corrosion-resistant alloys, mesh/plate designs for shallow installations, chemical enhancement etc.

- Integration with renewable energy / off grid charging sites, where solar and battery sources power chargers, may require earthing design to account for isolation, floating grounding, and ensuring a safe reference to the earth.

From Standards to Practice: EV Charging Earthing Examples

Here are concrete examples or regulatory cases in India which highlight the importance of proper earthing for EV charging:

- The Ministry of Power’s 2024 Guidelines mandate earthing for EV Charging Infrastructure, requiring earth continuity monitoring systems and safety/device compliance to ensure the supply is disconnected if earthing fails.

- The Central Electricity Authority (CEA) (Safety Provisions) Schedule-XVII requires that all EV charging stations use the TN system of earthing, as specified in IS 732, and that RCDs be set to operate at 30 mA or less.

- Bureau of Indian Standards (BIS) standard IS 17017 specifies safety norms for EVSE including connector safety, protection against shocks (which includes protective earth requirements).

These examples show that we are aligning more with international best practices, making earthing non-optional when designing or operating EV charging stations.

Conclusion

Earthing for EV charging infrastructure is a technical necessity, a legal obligation, and a safety imperative. Without a properly designed, installed, and maintained earthing system, even the best charger with high power, fast charging capability, and advanced features cannot guarantee safety, reliability, or long-term performance.

𝗔𝘁 𝗠𝗮𝗻𝗮𝘃, we design complete earthing ecosystems that ensure safety, reliability, and compliance for modern electrical systems. Our solutions go beyond design, we validate performance through advanced testing, conduct power system studies, delivering trusted, future-ready infrastructure.

If you are planning an EV charging station, ensure you invest time, expertise, and resources into soil resistivity testing, selecting the right electrode materials, coordinating safety devices correctly, complying with IEC / IS / CEA standards, and maintaining the station over time. Safe, reliable, and trusted EV charging depends not only on what you see (chargers, connectors, speeds) but also on what you don’t always see, the earthing for EV charging infrastructure beneath it all.

– Author: Priyadharsan